Water Leak Rate Testing Machine

Lauren Chiari

on

January 18, 2024

Water Leak Rate Testing Machine

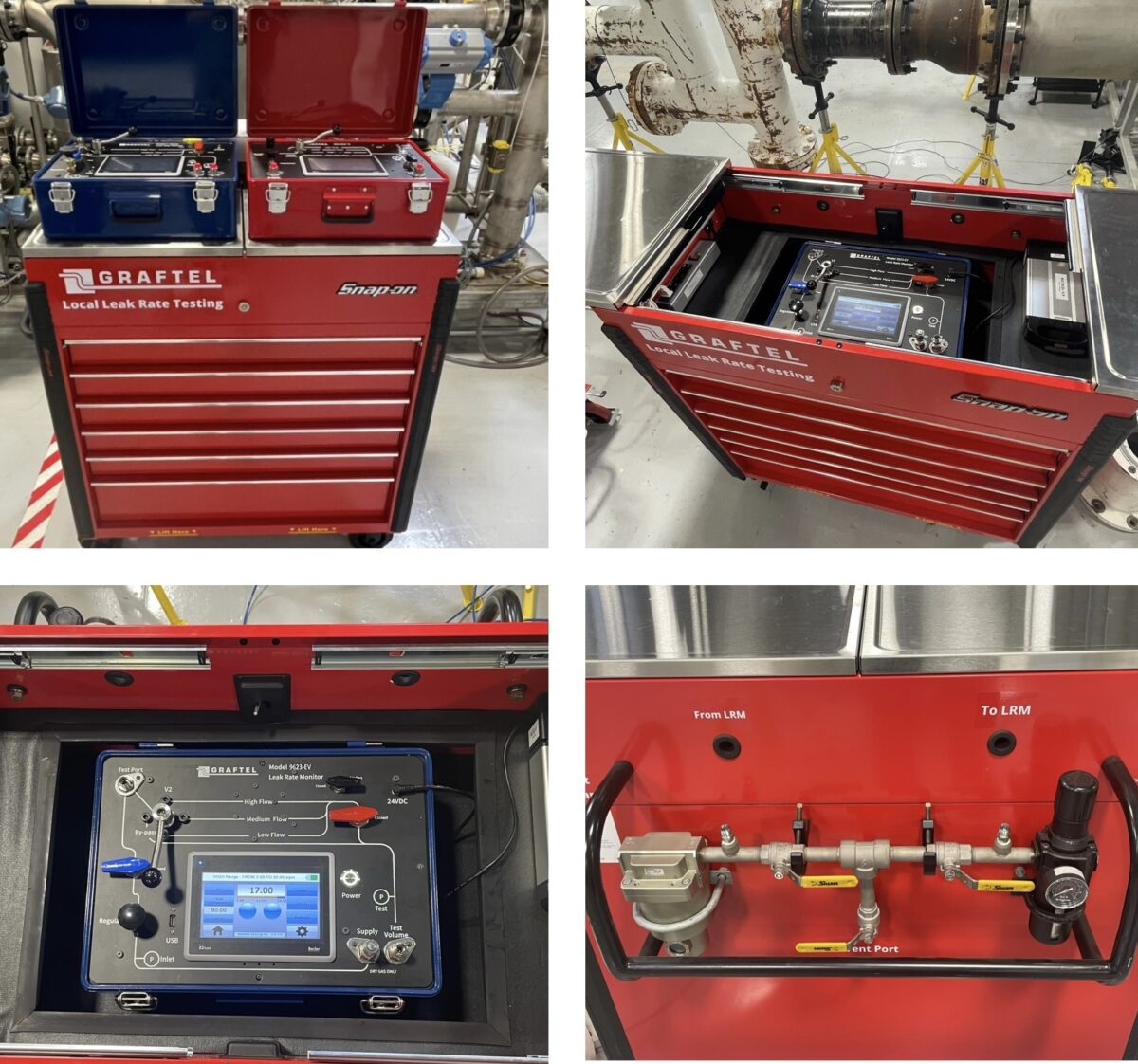

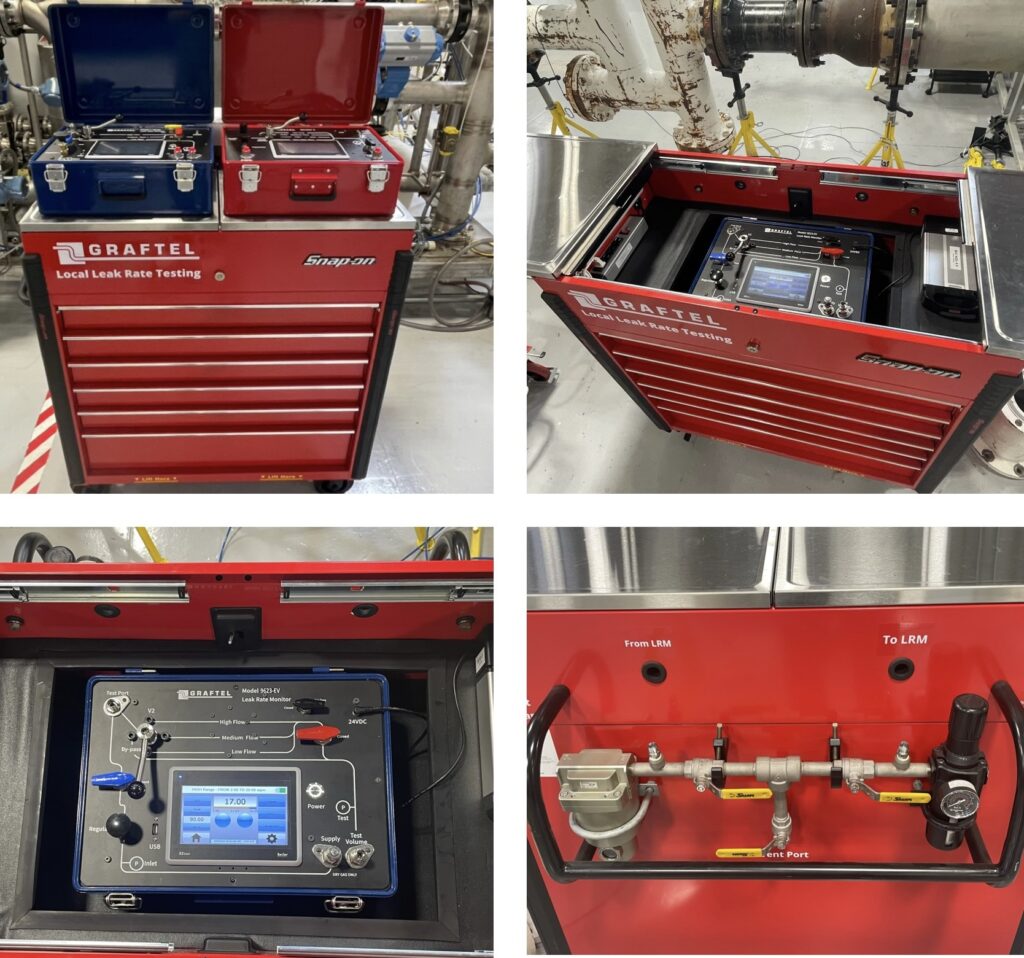

An easy-to-operate system designed to be used, this monitor allows for the precision testing of water tested containment isolation valves using plant demin or service water

Replace with The Model 9623-H2O, hydro leak rate testing machine.

Description:

9623-H2O Hydro Leak rate Monitor.

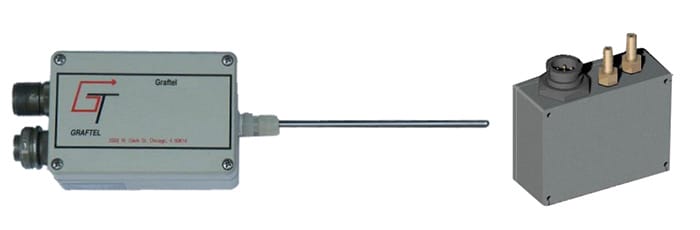

The Model 9623-H2O is an easy to operate system designed to be used This monitor allows for the precision testing of water tested containment isolation valves using plant demin or service water. This unit comes with 2 or three flow ranges, depending on your site-specific needs and two pressure channels, one to monitor inlet pressure and one for your test pressure.

The 9623-H2O quantifies the component under test’s leakage rate by maintaining a constant water pressure against the barrier being tested while measuring the water flow rate needed in order to maintain that pressure constant. A steady supply at a constant pressure of clean water is required to operate.

Flow Meter

Using two or three ranges, a 1000 to 1 turn-down ratio is achieved with a 1% of full-scale accuracy over each of the ranges. Each flow range is customer selectable to fit your site-specific needs.

Specifications

Flow rates

Range: 0 to 100 lpm (ranges are custom to each site, can be comprised of 2 or 3 flow meters)

Inlet Pressure Transducer

- Range: (0-150) psig

Test Pressure Transducer

- Range: (0-100) psig

- Accuracy: ±0.5psi

Please provide a valid form Id

Please feel free to contact our engineering staff to discuss your application needs at