ILRT Services

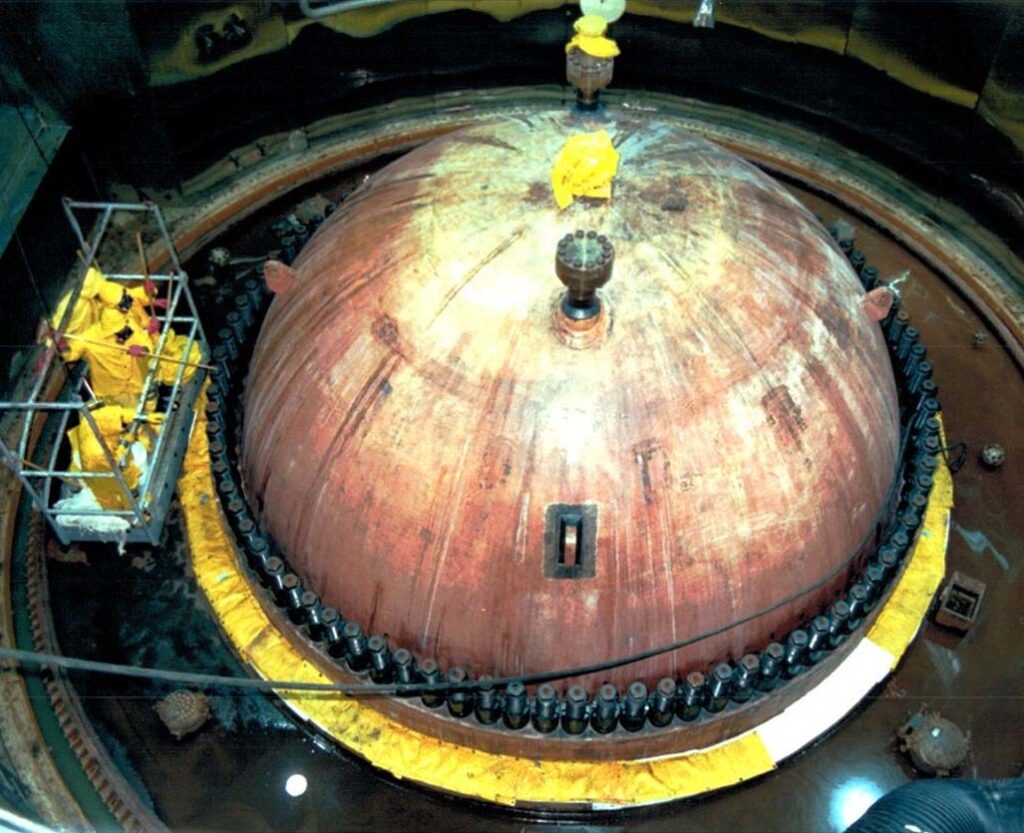

Complete ILRT Systems Testing Services By Graftel

Graftel is a supplier of ILRT and LLRT testing instrumentation as well as a consultant to the Nuclear Power industry. Graftel’s ILRT smart sensors have been in use in the U.S. since 1993 and have proven to decrease set up and test duration as well as minimize the amount of cabling and penetrations required. Graftel not only does complete testing services but also manufactures, services and calibrates all required instrumentation.

ILRT Procedure Reviews and Updates

Review plant procedures against 10CFR 50, App. J, ANS 56.8-1994, plant technical specifications, and plant flow diagrams/drawings.

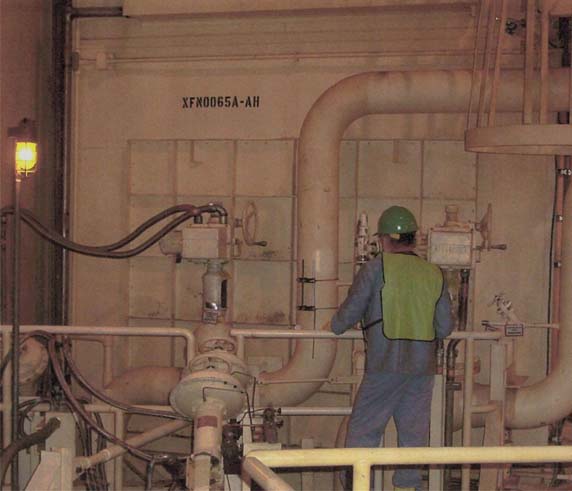

ILRT Setup and Performance Support

This service includes:

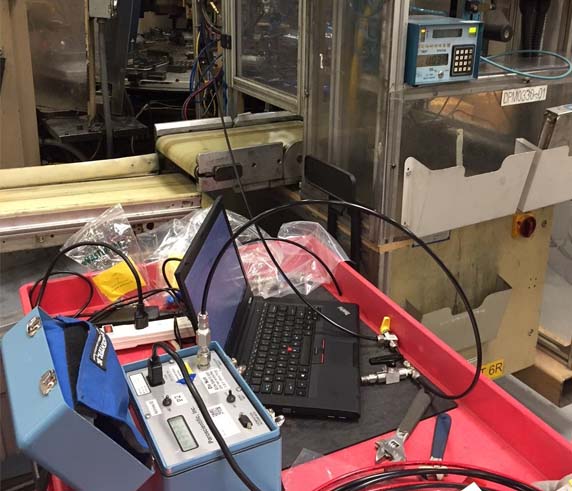

- Setup complete instrumentation and software system to ensure proper operation. Assist in sensor placement and coordinate completion of the check out procedures including equipment installation.

- Commencing with the final pre-ILRT containment inspection, our personnel begin 24 hour coverage. This coverage will continue through depressurization. During this sequence, personnel will generate the desired information to aid in the conduct of the ILRT.

- Graftel supplies ILRT software and 2 computers with 100% redundancy capable of independently performing all necessary data conversions and ILRT calculations. The software is able to trend the average temperature, dew point and pressure during pressurization, stabilization, actual test, verification and depressurization. The software is able to calculate stabilization criteria and leakage rate criteria using mass point and total time analysis techniques, including 95% upper confidence limit calculations and verification test criteria.

- ILRT Instrumentation and Cabling is supplied. The Data Acquisition is build into the sensors. 30 temperature sensors, 10 RH sensors, 2 pressure sensors and 2 flow meters are provided for measurement.