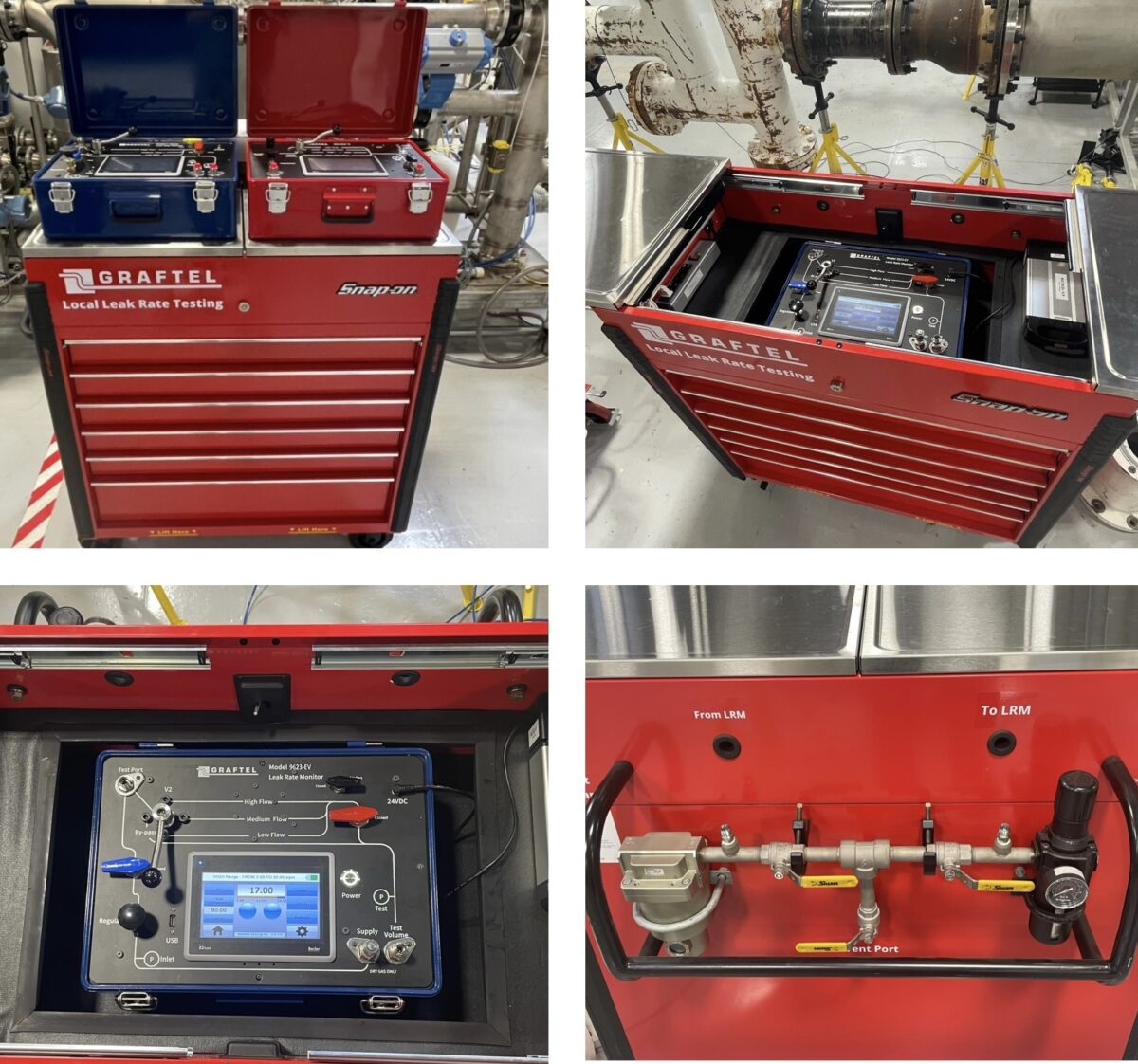

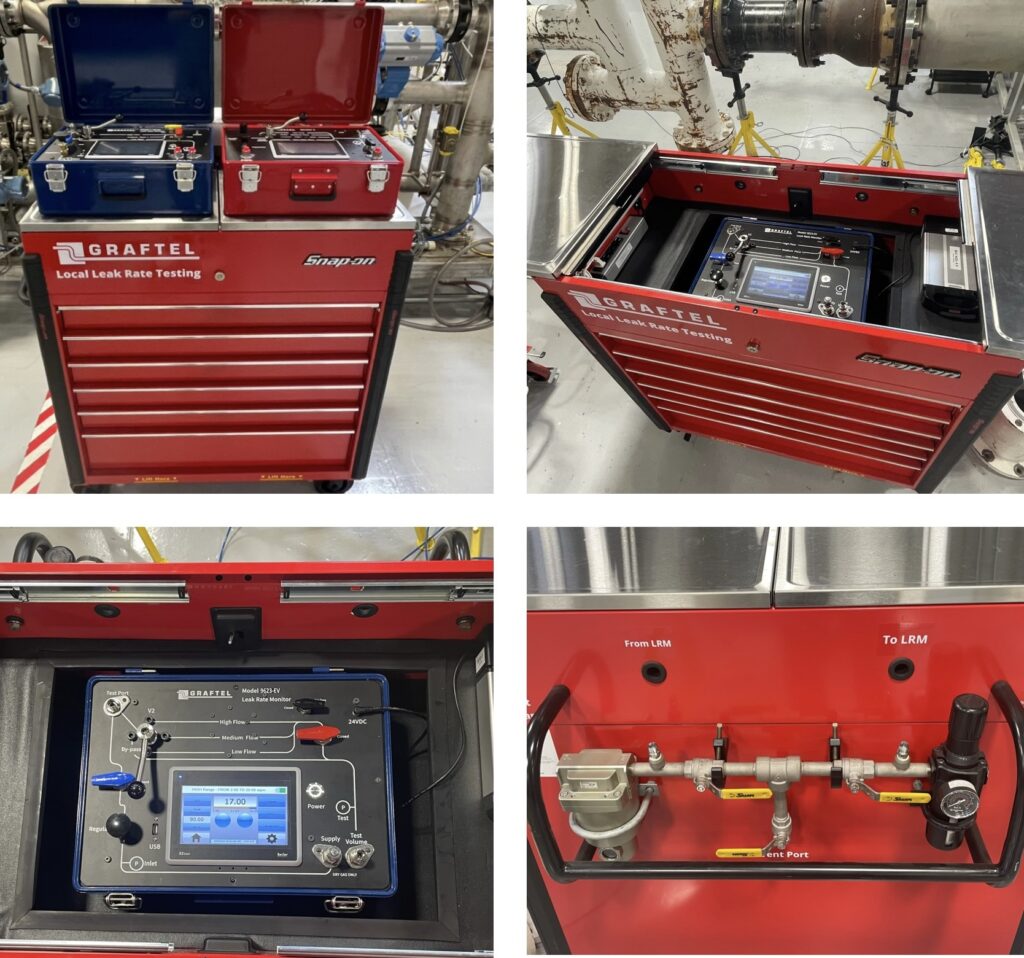

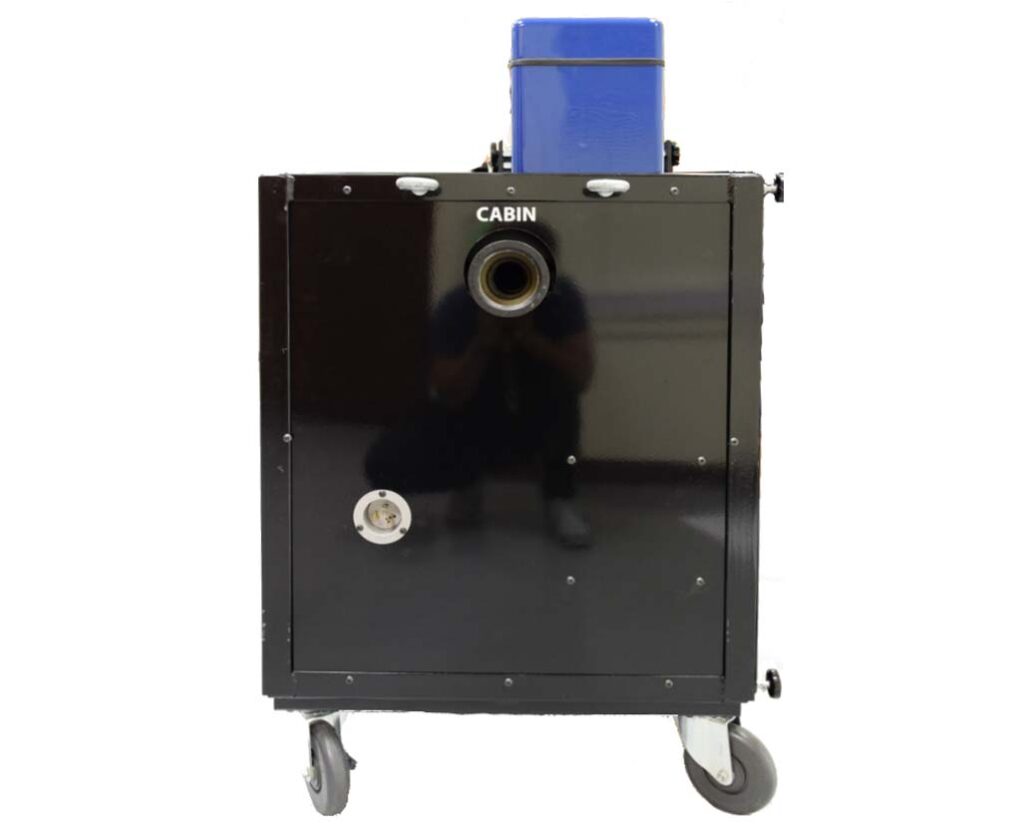

Model 9623-EV Leak Rate Monitor

graftel

on

January 16, 2024

Model 9623-EV Leak Rate Monitor

The Model 9623-EV is a new revision to it improves upon a proven design

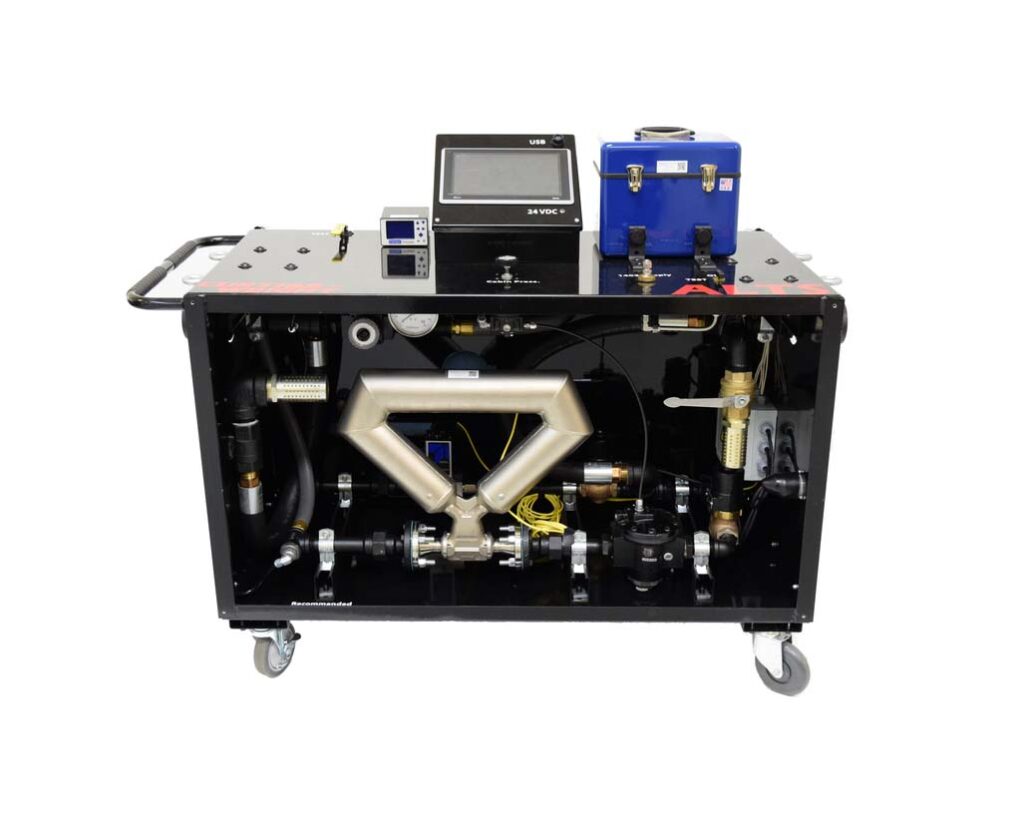

The Model 9623-EV is a revision built from an industry proven design. This unit can function with no power source by utilizing an internal internal air/electric generator.

It has three flow ranges and one pressure channel. The 9623-EV quantifies the component’s leakage rate by maintaining a constant gas pressure against the barrier being tested while measuring the gas flow rate needed in order to maintain that pressure constant. Using three ranges, a 1000 to 1 turn-down ratio is achieved with a 1% of full scale accuracy over each of the three ranges. Each flow range is customer selectable. Full scale flow ranges up to 400 slpm may be ordered. This same unit may also be used to perform temperature compensated pressure decay tests on large volumes.

High Accuracy Pressure Regulator

- Maximum Inlet Pressure: 250 PSIG

- Regulated Test Pressure: 5 to 140 PSIG

Ruggedized Color Touch Screen Display

- 7” Widescreen, 800 x 480 pixel

Three Flow Ranges

- Laminar element flow meters

- Full Scale of 212 SCFH

- 10 to 1 Turn-Down Ratio Recommended

- Accuracy: 1% of Full Scale

- Repeatability: 0.5% of Full Scale

- Max Pressure: 150 PSIG

Pressure

- Full Scale: 5 to 140 PSIG

- Accuracy: 0.25% of Full Scale

Power

- 24 VDC wall power supply

- Internal battery or internal air/electric generator

Please call or email for information [email protected]

Please feel free to contact our engineering staff to discuss your application needs at