Leak Rate Monitor Accessories

Graftel offers a full line of accessories to fit your complete LRM needs

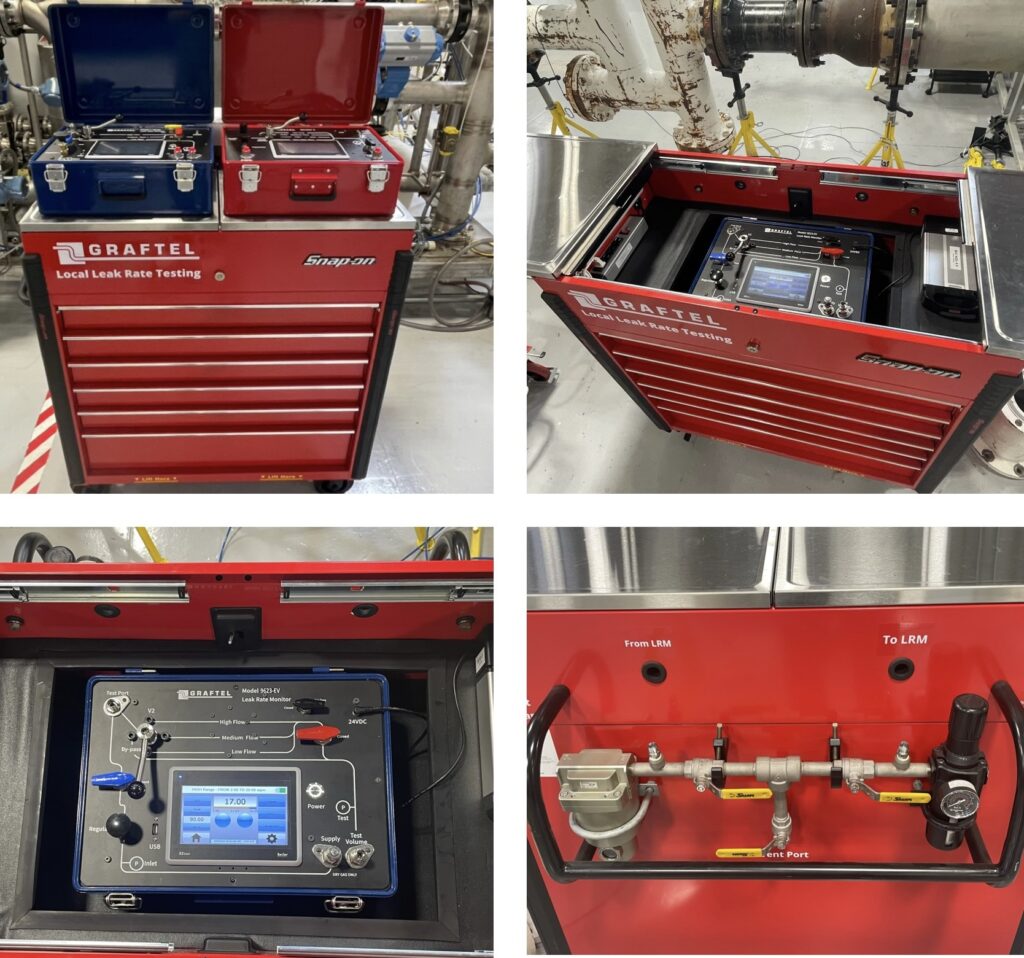

RCXD17 Mobile Utility Cart

The ultimate LRM accessory. The RCXD17 is a robust, versatile and portable workstation. The RCXD-17 is designed to securely store and operate LRMs. Any of Graftel’s standard sized leakage rate monitors (LRMs) will fit the workstation. This units also incorporates all available accessories and then some in one package. A mini unit is also available upon request.

This includes:

- Industrial power 4 port outlet (NEMA 5-15)

- Lockable caster wheels

- Lockable LRM storage & lockable tool storage drawers.

- Internal LED lighting

- Quick fill manifolds

- Pre filter

- Water trap

- High capacity rechargeable battery pack (20 hrs. additional run time)

Quick Fill Manifolds

Available Sizes:

- 1" Model# 9623QFM

- 1/2" Model# 9623QFM.5

This manifold allows for the quick filling of large volumes. This stainless steel manifold incorporates 1” and 1/2″ pipe, welded fittings and ¼ turn ball valves. This device allows for quick pressurization, testing as well as quick depressurization as shown below.

Check Nozzles

Available Sizes:

- 9623CN-26.5scfh-55.0psia-1/4”NPT.

- 9623CN-26.5scfh-55.0psia-3/8”NPT.

Just screw a check nozzle into the test port of the 9623-07 and set the monitor pressure to the test pressure labeled on the Nozzle Check. The 9623-07’s Nozzle Check Screen will tell you if the measured flow rate is within tolerance to the expected flow rate labeled on the Check Nozzle. All nozzles are 1/4” or 3/8 “ NPT and made from stainless steel. Each Check Nozzle comes with a NIST traceable certificate of calibration.

NPT Check Nozzle certified to flow 26.5 scfh with a 55.0 psia inlet pressure

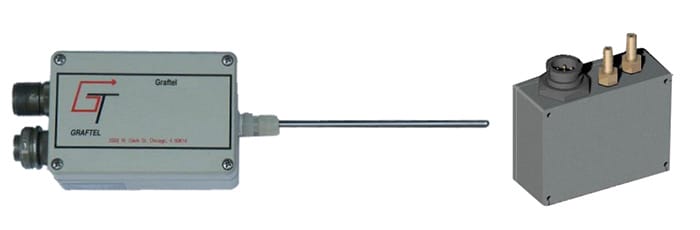

Pressure Decay Option

Part Numbers:9202 (Temp Sensor) & E-20 (High Accuracy Pressure Transmitter)

The quickest and most accurate way to leakage rate test a large volume, (such as airlocks) is using the pressure decay method. Graftel’s temperature sensor sensor Model 9202 can be used with high accuracy pressure transmitter to performing pressure decay tests on LRMs.

The LRM pressure decay screen reads pressure and temperature data from the 9202 and displays the leakage rate, air pressure and temperature.

Supply Air Conditioner/Pre-Regulator

Part Number: GT-1399K12

Most flow meter as found out of tolerances are due to the use of dirty, wet or oily supply air. This simple low cost device connected to the LRM inlet alleviates all of those conditions. This device both filters particles and traps any entrained oil or water from the supply air before it can enter the LRM

Max inlet pressure is 150 psig and the regulating range 0 to 125 psig.

This regulator can flow up to 1000 scfh, (approx 500 slm) at 100 psig.

Please call or email for information LR*****@*****el.com

Please feel free to contact our engineering staff to discuss your application needs at